Home > Our Business > Electronic Components > Electroplating Business

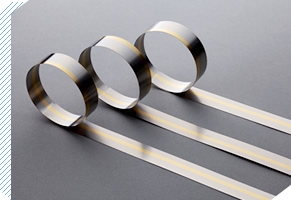

We respond quickly to the needs of our customers by supplying plated materials that are ideal for today's increasingly compact, slim and lightweight electronic products.

We have extensive knowledge of non-ferrous metals and electrolysis technology. We have applied these key strengths to the production of hoop-plated materials, including materials plated with gold, silver, tin and nickel.

Customers value our capacity to meet delivery schedules and ensure optimal quality management for mass-produced items, as well as our ability to manufacture high-quality customized products with short lead times.

Weight reduction is increasingly becoming a key requirement for products. TOHO ZINC is a leader in hoop-plating technology, which is used to apply thin, uniform surface treatments to various materials, including aluminum, stainless steel and copper products.

We offer optimized hoop-plating processes to meet the required specifications for the use of each material.

Our ability to exploit material characteristics, including high conductivity and resistance to corrosion, has made an important contribution to the development of advanced electronic product, including automobile parts, digital cameras, mobile telephones and industrial equipment.

Production process