Home > Our Business > Environment and Recycling Business > Zinc Oxide

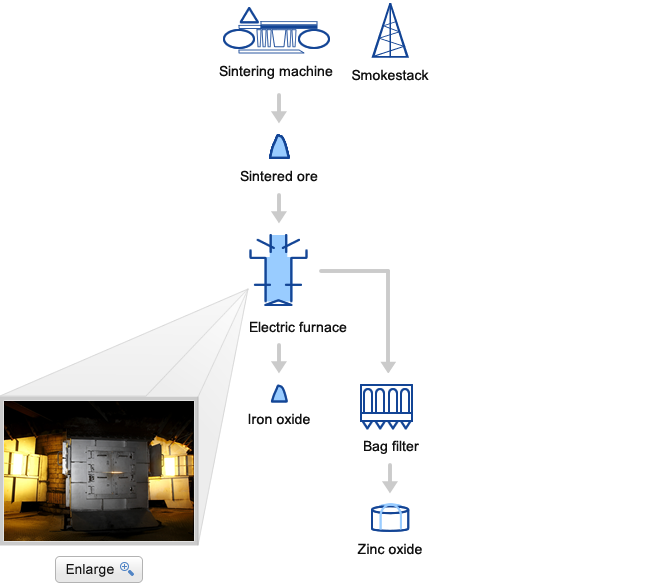

We use a technique that is unique in the world to produce recycled zinc oxide from electric furnace dust.

This zinc oxide manufacturing process produces zinc oxide through a direct method using electric furnace dust as the main raw material. The characteristic feature is that the commercial product is manufactured directly. We promote material recycling from "urban mines" as a bridge between electric furnace manufacturers and zinc oxide users. Our Onahama Smelter and Refinery prides itself on having an earth-friendly environmental preservation process that makes optimal use of non-ferrous smelting technology. We will continue to make improvements with the aim of improving product quality.

Zinc Oxide

The Onahama Smelter and Refinery produces zinc oxide from electric furnace dust and other materials using the direct method (American method). Marketed as Ginrei R, it is mainly used in rubber, which is the main constituent of tires.

Compositional Standards

| TOHO ZINC standards | JIS K1410 standards | |||

|---|---|---|---|---|

| Direct method (American method) |

||||

| Class 3 | Class 1 | Class 2 | Class 3 | |

| Appearance | - | White | White | - |

| Loss on drying | 0.3 or less | 0.3 or less | 0.3 or less | 0.3 or less |

| Purity | 99.0 or more | 99.5 or more | 99.5 or more | 99.0 or more |

| Water-soluble matter | 0.5 or less | 0.1 or less | 0.1 or less | 0.5 or less |

| Pb (%) | 0.20 or less | 0.005 or less | 0.03 or less | 0.3 or less |

| Cd (%) | 0.004 or less | 0.002 or less | 0.01 or less | 0.1 or less |

| Residue on sieve (%) | 0.1 or less | 0.1 or less | 0.1 or less | 0.1 or less |

| TOHO ZINC brand | Ginrei R | |||